Digital web-based shopping options have not only been flourishing since the pandemic, but have been the central sales channel in B2C and B2B business for years. Individual product presentation and configurator solutions are also increasingly taking center stage for furniture and furnishings. It’s no longer just about online showrooms or virtual staging of designer pieces. Especially when working with suppliers, fast web configuration of semi-finished products, variable carcase programs and even detailed individual part production is required. Fast, transparent and traceable communication channels save time and money. Software solutions often promise quick help and entice users with seemingly uncomplicated plug-in solutions. However, if the conceptual and necessary structural work in the areas of master data, digital processes and optimization of the product portfolio is neglected in advance, the introduction of new digital solutions is at risk of failing. Investment costs thus become sunk costs. For consistency in data-supported furniture production, three areas in particular need to be examined more closely: Data, processes and products.

The data required for end-to-end processes from the web to the machine is rarely available in the required orderly structure, but comes from a wide variety of heterogeneous sources within and outside the company. Structures and processes that have evolved over decades are not yet or only partially digitized. Comparable to a highway with occasional sections of cobblestones. Products or manufacturing information may originate from previously analog production processes and were developed with a focus on material costs or market trends, as data consistency still played a subordinate role in the past. These factors significantly hinder the implementation of digital variant configuration and associated software solutions.

L’Engineers’ tried-and-tested approach is based on the six phases of the quality management approach and lean management methods. A common target image is defined on the basis of existing and required data, processes and products. It describes exactly which products are to be manufactured in which processes, based on which data. Differentiating between several levels of digital availability is a decisive step here. The process chain and products are analyzed according to existing digitalization stages, automation options are identified and cost drivers are reduced. Based on these findings, an initial prototype is created, which is constantly compared with the target image and corrected. The challenges lie in the details, as the most important findings from previous projects show:

- Lost in translation: Do not underestimate the translation effort between real data and valid information.

- The discovery of slowness: The slowest sub-process determines the speed of the entire production chain.

- Less is more: Generating more data does not always mean closing existing gaps.

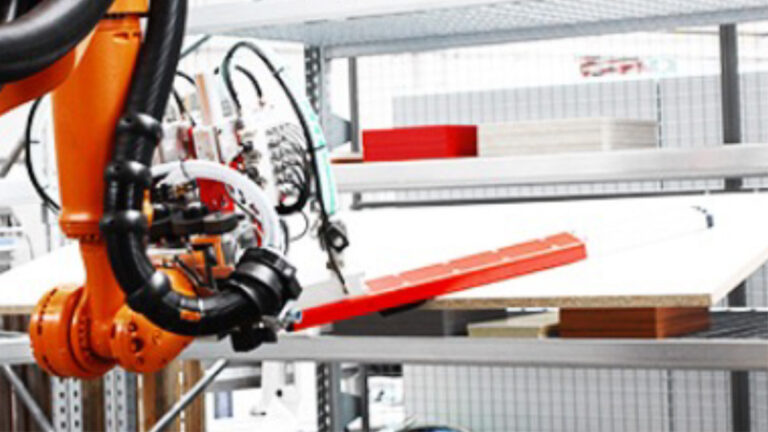

As an experienced boutique consultancy from the south of Germany, L’Engineers focuses on precisely these issues. An interdisciplinary team with years of expertise has already been able to combine virtual reality with manufacturing reality on several occasions. As a result, individual production environments were developed in a lean, efficient and solution-oriented manner. Whether you are a small industrial wood manufacturer, an extended workbench as a supplier or a globally active kitchen furniture manufacturer, the specialists at L’Engineers design individual structures for end-to-end data-supported furniture production.